User:Cdonnelly93/sandbox

Quartz Fiber

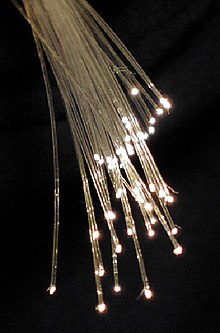

| Quartz Fiber | |

|---|---|

Bundle of High Purity Silica Fibers | |

| General | |

| Category | Fused Silica |

| Formula (repeating unit) | 99.95% SiO2 |

| Identification | |

| Formula mass | 60.08 g/mol |

| Color | White/Transparent |

| Density | 2.20 g/cm^3 |

| References | [1] |

Quartz fibers are very pure, fused silica glass fibers composed of over 99.95% silicon dioxide.[1] The fibers are primarily used to reinforce a larger group of materials called composite materials.[1] [2]

Quartz fibers are long-continous fibers and are produced from continous strands of quartz of either 120 or 240 individual filaments that are twisted into heavier fibers.[1] Quartz fibers have high temperature strength, tensile strength, chemical stability, hydrophobicity, and electrical resistivivity.[1] [3] [4] The fibers also have a lower density, higher stiffness, and require greater elongation to break compared to typical glass fibers such as E-Glass, making the quartz fibers candidates for improving the mechanical abilties of materials.[5]

Quartz fibers have become a focal point of many researchers involved in chemical engineering, composite materials, and polymer science. Some of the prominant uses of these fibers include fabric yarns, electrical insulators, increasing the strength and temperature resistance of fabrics, improving the floating capability of boats, and enhancing materials in the aerospace industry.[1] [4] [5] These fibers cost far more than ordinary glass fibers, reaching up to $150 per pound for the more pure forms. The high quality quartz needed for quartz fiber is very rare, mainly mined in Brazil.[2]

Properties[edit]

Table 1 - Chemical and Physical Properties[edit]

| Property | Value |

|---|---|

| Specific Gravity | 2.20 |

| Tensile Strength (one filament) | 870 ksi |

| Specific Heat | 7500 Joules/kg/oC |

| Coefficient of Expansion | .54x10^-6 cm/cm/oC |

| Thermal Conductivity | .0033 Cal/sec/cm/oC |

| Dielectric Constant | 37.8 GHz |

| Hydrophobicity | Super Hydrophobic potential |

| References | [1] [4] |

Naming[edit]

Table 2 - Common Examples[edit]

| Strand Type | Number of Filaments | Diameter (10^-5in) |

|---|---|---|

| QCG 300 1/0 | 119 | 45 |

| QCG 300 2/0 | 240 | 35 |

| QCG 300 1/2 | 240 | 35 |

| QCG 300 2/2 | 480 | 35 |

| QCG 300 2/8 | 1920 | 35 |

| References | [6] |

In Table 2 (above), the column under strand type represents the names of different quartz fibers. Quartz fibers are named using the same method as typical glass fibers such as E and S glass fibers. Each letter and number specifies a characteristic of the fiber.[6]

- The first letter in the name of a quartz fiber is always Q and it indicates that the fiber is composed of quartz.[6]

- The second letter represents the type of filament that the fiber is composed of. It is C for quartz fibers because they are created by continuous filaments.[6]

- The third letter stands for the filament diameter. Most quartz fibers will be assigned the letter G with diameters usually around .00036in.[6]

- The first number represents 1/100 of the normal number of yards of the fiber per one pound of fiber.[6]

- The second number represents the basic number of strands in the fiber. The first part is the number of twisted strands and the second is the number of strands plied together. Multiply these two digits to get the total strands in one fiber. A zero is taken to be one for the multiplication.[6]

Other Facts[edit]

Quartz fibers are usually coated with an organic layer containing a silane coupling agent that is compatable with many resin systems.[1] Quartz fibers also have the highest strength-to-weight ratio of any high temperature material.[1] The fibers can be used for temperatures much higher than most glasses, such as E glass or S glass. The fibers maintain high perfomance even up to temperatures of 1920oF and do not melt or vaporize until temperatures are greater than 3000oF.[1] Also, quartz fibers maintain most of the characteristics and properties of solid quartz.[1] Quartz fibers are very chemically stable and are not affected by common halogens and acids.[1] However, the fibers should not be used in the environment where strong alkalides are present.[1] In addition, the quartz fibers can be put into water without damage and have very low thermal expansion.[2]

Current Uses[edit]

Quartz Fiber Dosimeter - One use of quartz fibers is the quartz fiber dosimeter. The quartz fibers are used for electrical conductance to measure levels of radiation in the surrounding environment.

Aircraft Radomes - Quartz fibers are used in the aerospace industry for different parts of aircrafts. The main part these fibers are used for is the aircraft radome.[5] Because of thier electromagnetic properties and high strength, quartz fibers can be used to protect antennas against unwanted microwaves and against bad weather.[5]

Electrical Insulators - The low dielectric constant and low loss tangent make quartz fibers great electrical insulators as well.[1] The fibers are used as insulators in electrical wires.[1]

High Energy Materials - The high temperature stability of the fibers make them very applicable to materials that are used at high temperatures and high energies. The quartz fibers can be used to improve the heat resistance of materials, such as epoxy composites.[1]

Adhesives - Quartz fibers are very compatible with several adhesives and resin systems.[1] The fibers can be used to improve the bonding ability of epoxy.[1]

Future Applications[edit]

Due to thier mechanical properties, quartz fibers have a broad range of applications.

- Clothing - Quartz fibers can be woven into textiles and clothing to improve the durability and strength of the material.[1] Because quartz fibers are not affected by halogens or most acids, they are candidates for protective wear. The fibers can be woven into labrotory coats to protect against chemicals for example.[1]

- Industrial and Commercial Fabrics - Since quartz fibers have the highest strength-to-weight ratio of any high temperature material, they have potential to improve the flexibility and loading capacity of fabrics.[1]

- Stealth Applications - In addition, quartz fibers offer uses in stealth applications because of the fibers' low electrical resistivities.[1]

- Anti-Radiation - Quartz fibers can also be used for protection against radiation. The fibers show no change in optical properties or tensile strength when exposed to radiation of about 500 MeV.[7]

- Boats and other Watercrafts - Quartz fibers can be used in the boat industry.[4] When applied to the composite materials making up the bottom of a boat, the fibers help increase the hydrophobicity of the material, making the boat float better and move smoother.[4]

Experimentation with Quartz Fibers[edit]

Researchers have demonstrated several ways to further improve the mechanical properties of quartz fibers.

Effect of Silicon dioxide doped boron nitride[edit]

Adding silicon dioxide and boron nitride to the surface of quartz fibers greatly improves the fibers' mechanical strength. This addition may help double the tensile strength of the quartz fibers, increasing the fibers applications to strong materials. The silicon dioxide and boron nitride coating helps seal the defects of the fiber structure, as well. [3]. This enables the quartz fibers to withstand greater heat.

Nanotechnology[edit]

One application of quartz fibers is nanotechnology. Incorporating carbon nanotubes or nanofibers into materials requires materials with strong mechanical properties, which quartz fibers have. Quartz fibers can be prepared easily by chemical vapor deposition. Carbon nanotubes can help improve the electrical conductance and shear strength of quartz fibers up to 15% with low amounts of carbon nanotubes. [8].

See also[edit]

Notes[edit]

- ^ a b c d e f g h i j k l m n o p q r s t u v "Composite Materials Handbook-MIL 17, Volume III:." Google Books. N.p., n.d. Web. 03 Nov. 2012. <http://books.google.com/books?id=wnM6ctnpiwgC>.

- ^ a b c "Quartz Fibers." Quartz Fibers. N.p., n.d. Web. 03 Nov. 2012. <http://composite.about.com/library/glossary/q/bldef-q4372.htm>.

- ^ a b "NU Libraries: Please Login." NU Libraries: Please Login. N.p., n.d. Web. 03 Nov. 2012. <http://0-www.sciencedirect.com.ilsprod.lib.neu.edu/science/article/pii/S0169433211017430>.

- ^ a b c d e "NU Libraries: Please Login." NU Libraries: Please Login. N.p., n.d. Web. 03 Nov. 2012. <http://0-www.sciencedirect.com.ilsprod.lib.neu.edu/science/article/pii/S0169433211006532>.

- ^ a b c d "The Fiber : CompositesWorld." The Fiber : CompositesWorld. N.p., n.d. Web. 03 Nov. 2012. <http://www.compositesworld.com/articles/the-fiber>.

- ^ a b c d e f g http://www.hexcel.com/Resources/DataSheets/Brochure-Data-Sheets/HexForce_Technical_Fabrics_Handbook.pdf

- ^ "NU Libraries: Please Login." NU Libraries: Please Login. N.p., n.d. Web. 04 Nov. 2012. <http://0-www.sciencedirect.com.ilsprod.lib.neu.edu/science/article/pii/S0168900202010677>.

- ^ "NU Libraries: Please Login." NU Libraries: Please Login. N.p., n.d. Web. 03 Nov. 2012. <http://0-pubs.acs.org.ilsprod.lib.neu.edu/doi/pdf/10.1021/ie202306v>.

References[edit]

The reference numbers correspond to the order in which they were used and correspond to the same numbers in the notes section.

1. [Anonymous]. 1999. The composite materials handbook-mil 17: materials, usage, design, and analysis. Volume 3. Technomic publishing co, material sciences corporation.

2. October 2012. Quartz fibers. About.com composite materials. <http://composite.about.com/ library/glossary/q/bldef-q4372.htm>. Accessed 2012 November 4.

3. Wang S, Zheng Y. The effect of SiO2-doped boron nitride multiple coatings on mechanical properties of quartz fibers. ASS. 2012; 258 (7): 2901-2905.

4. Cheng X, Dong W, Guan S, Hang Y, Jiang Z, Li J, Ma Z, Qui W. A simple method to prepare miniature quartz fiber boats with superhydrophobicity. ASS. 2012; 258 (6): 2038-2042.

5. October 2012. The fiber. Composite world. <http://www.compositesworld.com/articles/ the-fiber>. Accessed 2012 November 4.

6. Hexcel co. December 2010. Technical Fabrics Handbook. < http://www.hexcel.com/ Resources/DataSheets/Brochure-Data-Sheets/HexForce_Technical_Fabrics_Handbook.pdf>. Accessed 2012 November 4.

7. Akchurin N, Akgun U, Ayan S, Bruecken P, Dumanoglu I, Eskut E, Fenyvesi A, Kayis A, Koca N, Makonyi K, and others. Radiation-hardness studies of high OH− content quartz fibres irradiated with electrons. NIMPR. 2002; 490 (3); 444-455.

8. Jin L, Li C, Su D, Zhang L. Direct growth of aligned carbon nanotubes on quartz fibers for structural epoxy composites. IECR. 2012; 51 (13): 4927-4933.